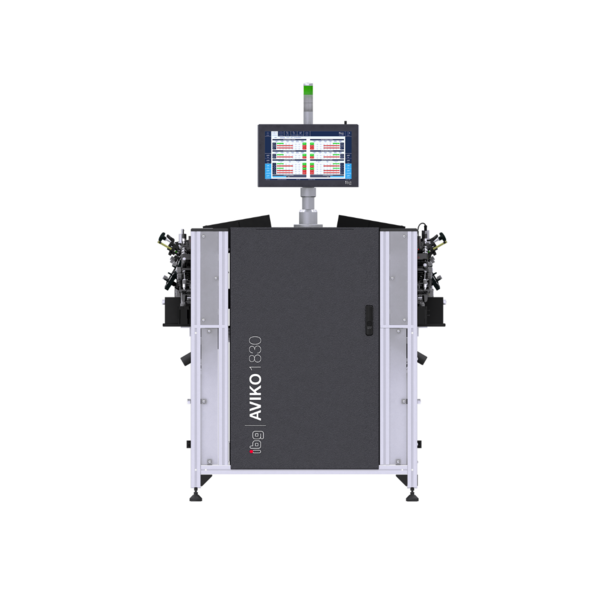

AVICO G3 COMPACT: Microstructure Inspection and Precision Ball Inspection

AVIKO's ball inspection system provides swift, non-destructive evaluation of balls at speeds of up to 34,000 pcs/hr. Specialized probes match your ball material, assessing both surface and sub-surface characteristics. Elevators, conservation units, demagnetizers, and packaging machines are among our available accessories, all designed to enhance your inspection process. For seamless integration and improved efficiency, explore our comprehensive automation solutions.

Precision inspection from 2 mm to 30 mm with advanced sensors

AVIKO standard machines range from 2mm to 30mm. These machines incorporated probes for crack detection, laser sensors for surface defect detection, and vibration sensors for ovality detection. The core principle of ball rotation for 100% surface scanning is based on control rollers.

AVIKO G3 COMPACT: Advanced Microstructure Testing for Precision Ball Sorting

AVIKO G3 COMPACT has the option to be upgraded with an additional test for the microstructure. The microstructure test is capable of sorting out the balls with different materials as well as different hardness. Due to the eddy current technology used, only ferromagnetic steels can be sorted out with this test. An eddyvisor S unit and eddy current probe are used for testing.

Order Information

| Model | Sorting Diameter (mm) | Order Number |

|---|---|---|

| AVIKO 0203 G3 COMPACT | 1.984 – 3.175 | K 097 400 |

| AVIKO 0306 G3 COMPACT | 2.778 – 6.350 | K 097 450 |

| AVIKO 0610 G3 COMPACT | 5.556 – 10.319 | K 097 500 |

| AVIKO 1014 G3 COMPACT | 9.500 – 14.286 | K 097 550 |

| AVIKO 1419 G3 COMPACT | 13.494 – 19.050 | K 097 700 |

| AVIKO 1830 G3 COMPACT | 18.000 – 30.163 | K 097 750 |

Scan Speed

* Scan speed is calculated for both sides working in unison. (Same diameter)

| Machine | Min. | Ball | Max. | Ball | Min. | Scan Speed | Max. | Scan Speed |

|---|---|---|---|---|---|---|---|---|

| [mm] | [inch] | [mm] | [inch] | Standard [pcs/hr] | Aerospace [pcs/hr] | Standard [pcs/hr] | Aerospace [pcs/hr] | |

| AVIKO 0203 G3 COMPACT | 1.984 | 5/64 | 3.175 | 1/8 | 34 100 | 32 100 | 30 500 | 28 100 |

| AVIKO 0306 G3 COMPACT | 2.778 | 7/64 | 6.350 | 1/4 | 32 800 | 30 500 | 24 500 | 21 600 |

| AVIKO 0610 G3 COMPACT | 5.556 | 7/32 | 10.319 | 13/32 | 26 200 | 19 000 | 17 600 | 11 900 |

| AVIKO 1014 G3 COMPACT | 9.525 | 3/8 | 14.286 | - | 18 800 | 16 700 | 11 600 | 9 300 |

| AVIKO 1419 G3 COMPACT | 13.494 | 17/32 | 19.050 | 3/4 | 12 800 | 10 600 | 7 900 | 6 700 |

| AVIKO 1830 G3 COMPACT | 18.000 | - | 30.163 | 1-3/16 | 7 700 | 6 600 | 3 500 | 2 800 |

| AVIKO 0203 COMPACT | AVIKO 0306 - 1419 COMPACT | AVIKO 1830 COMPACT | |

|---|---|---|---|

| Dimensions (L×W×H) | 1000 × 1201 × 1920 | ||

| Weight | 170 (kg) | 170 (kg) | 200 (kg) |

| Sorting groups | 3 (OK, EOT probe rejection; EVT/ECT probe rejection) | ||

| Input Power (230V) | 230V, 50Hz/60Hz (Type E plug) | ||

| Input Power (110V) | 110V, 50Hz/60Hz (Type B plug) |

| SCAN AREA width | MAX. DEFECT size | |

|---|---|---|

| Electric optical probe | 1.2 mm | Spot defect Ø 600 μm |

| Electric vibration probe | - | Deep flat 700 μm |

| Eddy current probes | 2 mm | Crack defect 750 × 50 × 50 (μm) |

Contact Us