High-speed, high-performance fastener testing made easy

Case study of advanced Eddy Current NDT solutions from ibg installed on Dimac MCV4 100% inspection and sorting machines for automotive fasteners

Problem Summary

Fasteners for the automotive industry require highest quality heat treatment for specific hardening results, followed by 100% inspection (usually NDT) plus labbased sample control.

At the same time the pressure on production concerning cycle time, cost, productivity, and flexible batch sizing is increasing. The market for qualified labor is tight in many regions of the world. This requires for the NDT part a most reliable, rapid, but at the same time easy to use and industry accepted testing. For the machine builder this translates into the need for an easy to integrate testing solution.

Solution

ibg and Dimac worked closely together and developed advanced solutions for non-destructive-testing of heat treatment of fasteners, not only for automotive customers.

The advanced and easy-to-use NDT structure testing instrumentation by ibg is able to learn what a correct microstructure looks like and what is an exceptional outlier even from a small range of regular parts. Fields of tolerance around the average define what classifies as ok parts. All deviations from that move into the not ok part classification for later lab inspection and possibly adjustment. This loop enables continuous machine learning. Part of that solution is the use of ibgs´ Preventive Multi Frequency Testing (PMFT) Technology based on eight frequencies and their 3rd and 5th harmonics within one run in order to generate a broader imprint of the microstructure. High resolution sensors and specific compensation technology ensures consistent results even under changing conditions. An intuitive visual user interface makes it easy to operate. The integration of the ibg system in Dimac m chines of the latest generation combines all of that outstanding features into a turnkey solution for automatic 100% inspection and sorting served with fast and competent global on-site as well as remote support.

Benefits

- Testing and sorting is based on a limited set of regular parts

- Reduced operator training, thus allowing qualified worker-self-inspection without a lab expert at hand, e.g. at night-shifts

- The ease of use provides additional flexibility for production schedulers in terms of staffing and batch-sequencing

- Changes of temperature within certain ranges is automatically compensated for reliable results even under difficult conditions, contributing to the ease of use

- Easy reshaping of the fields of tolerance based on results from the laboratory supported by machine learning

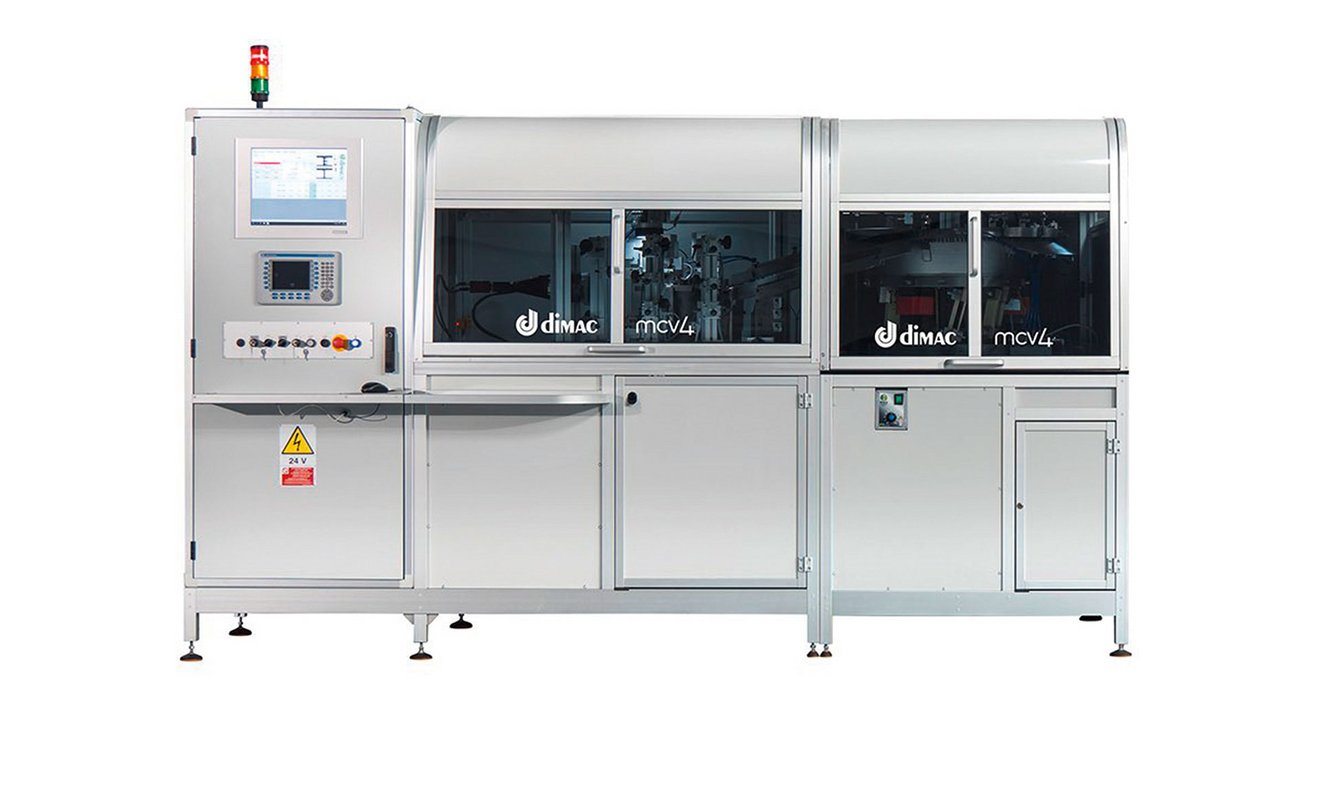

- In combination with additional unique system features, the new Dimac MCV4 machine allows significant shorter cycle-times and higher throughput, while being easy to operate

testing and ibg crack test probe at work

Background

Part of the constructive concept for safety of especially electric vehicles is the use of special fasteners, which partly replace spot welding as a connection technology in Body-in-White (BiW) applications.

Sophisticated heat treatment procedures are therefore an important step within the manufacturing of these fasteners, followed by a 100% non-destructive testing (NDT) of the microstructure of the faste ner. The production teams, the lean manufacturing teams and the quality teams of fastener manufacturers are challenged with conflicting objectives.

- 100% quality of fasteners according to the specification

- Ongoing demand for cost reduction and productivity gains (tact time, flexibility, labor, …)

- Shortage of qualified staff

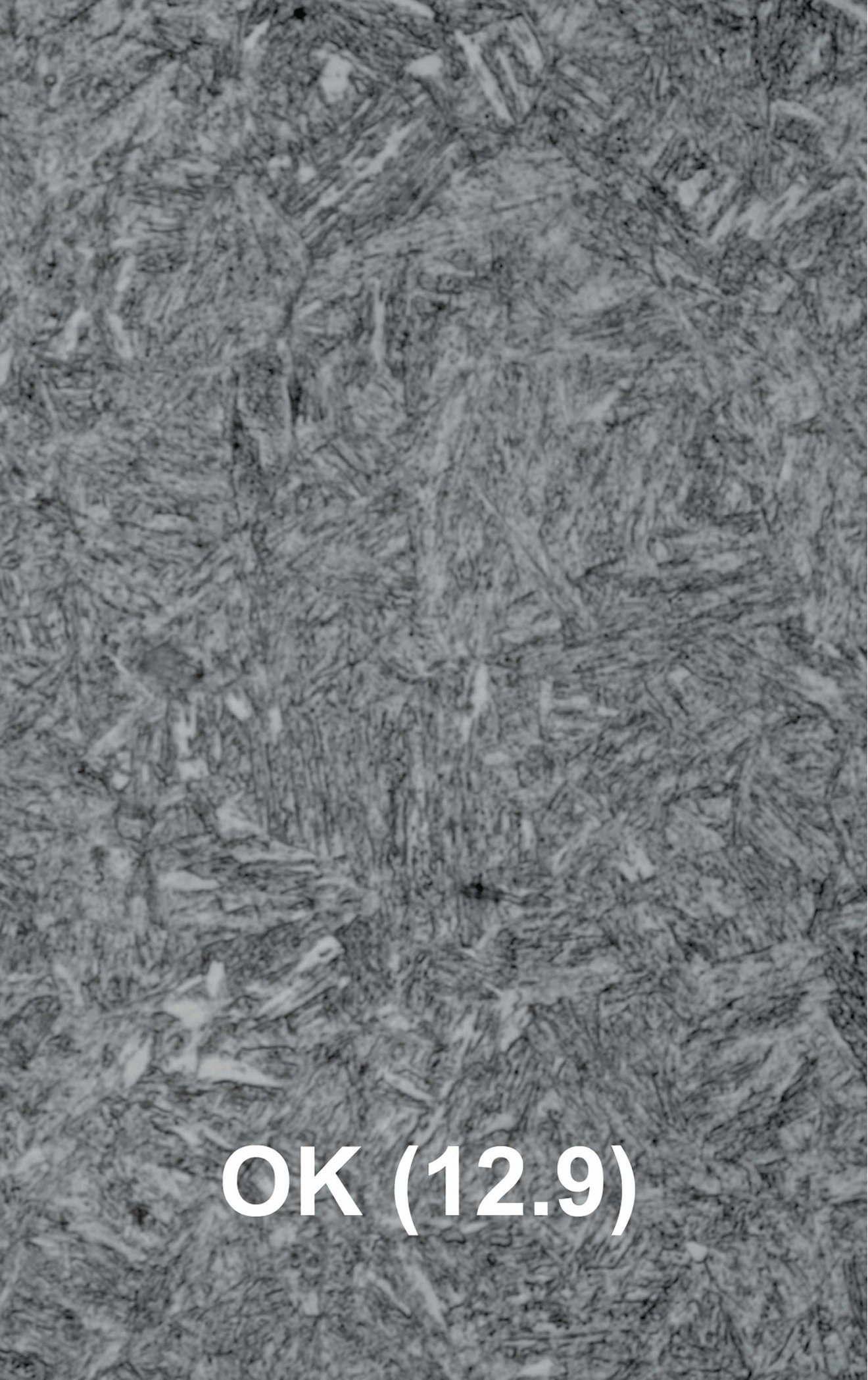

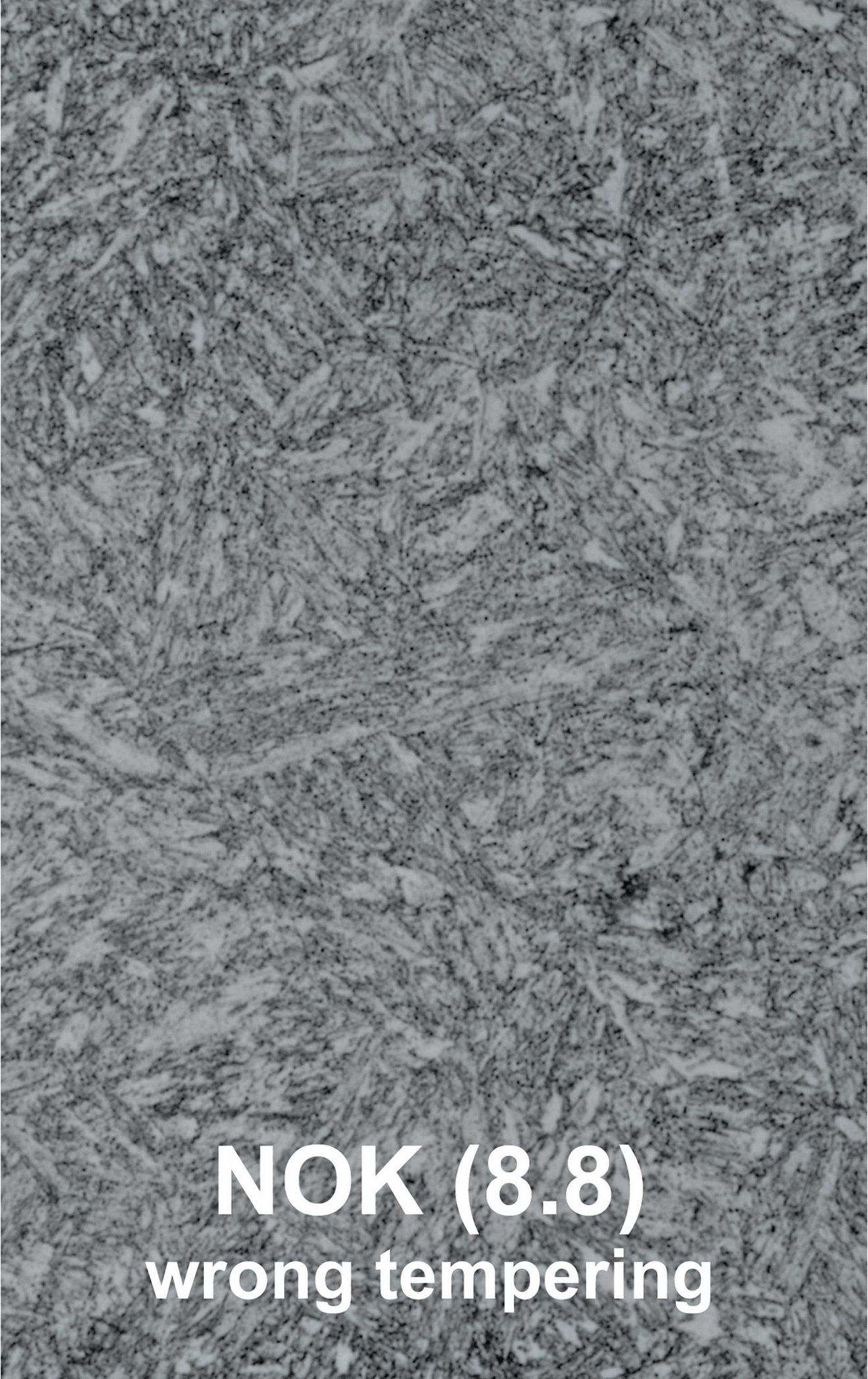

In addition to the manufacturing and machining of fasteners the effective and efficient heat treatment testing and sorting is critical to improve on the challenges above. Key testing parameter for heat treatment is the structural homogeneity of the desired microstructure. The homogeneity may vary due to the complex nature of the processing and heat treatment steps. It therefore requires accurate, cost-effective and high-speed 100% NDT testing to detect potential issues of parts as shown in Fig. 2 below. Traditional single frequency NDT structure testing can focus on just one type of defect caused by a wrong heat treatment (e.g. hard vs. soft). This concept is blind for random not-ok parts caused by other unexpected problems and can´t work as a preventive solution. More and more automotive companies realize that limitation and ask for better, multi-frequency solutions. That does require a faster speed and much higher performance of the testing solution overall.

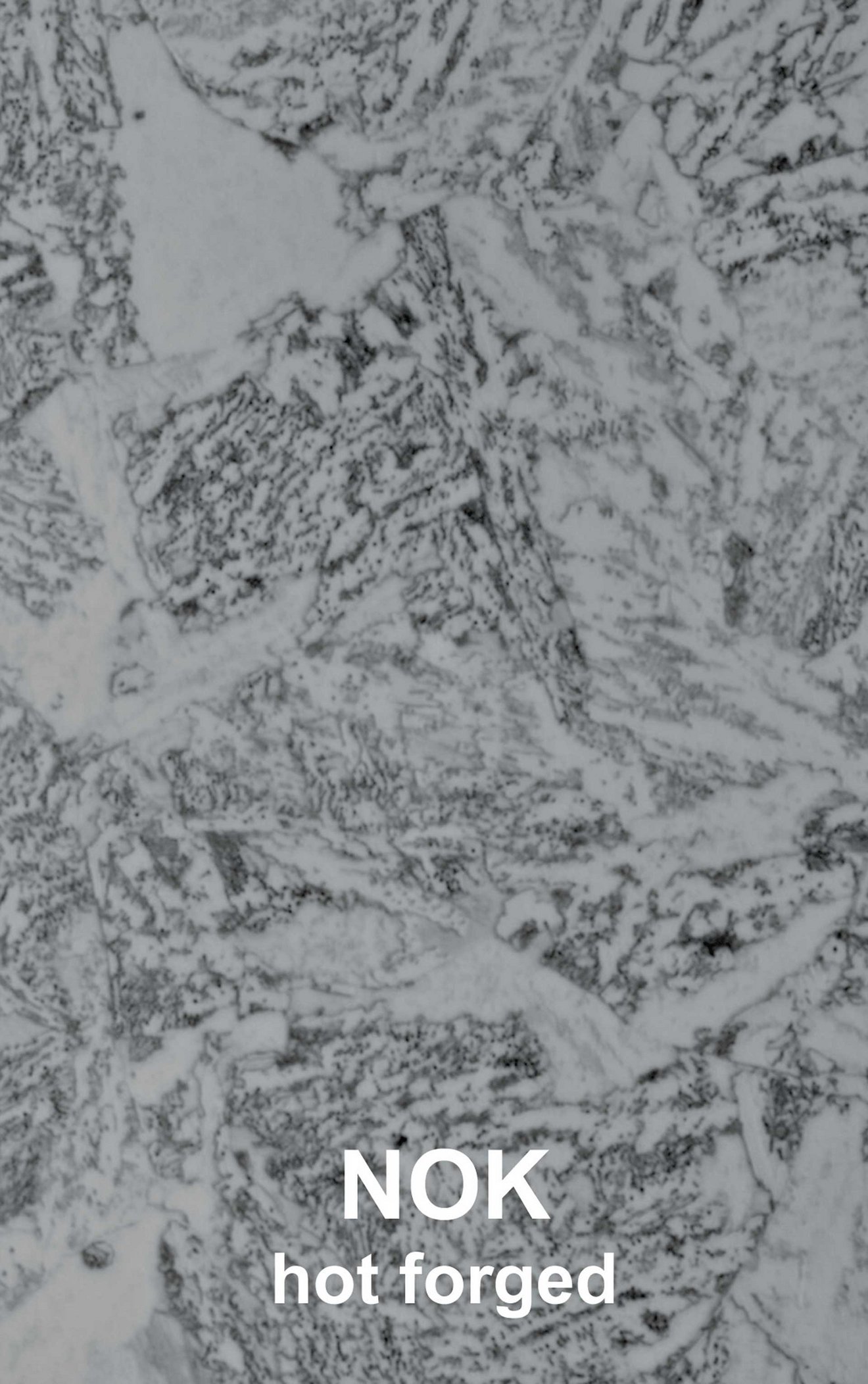

Fig. 2 – Microsection of 34Cr4 screws (magnification 1000x) – from left:

OK part

(quench and temper, Class 12.9, 401 HV)

expected NOK part

(quench and wrong temper, Class 8.8, 297 HV)

unexpected NOK part

(hot forged, 289 HV) – Copyright: Arnold Horsch

Improvement

The Dimac MCV4 machines fulfil the upraised demand of automotive customers based on several years of intense research and development. The combination of an advanced microstructure testing by ibg and several camera based inspections make up for the difference.

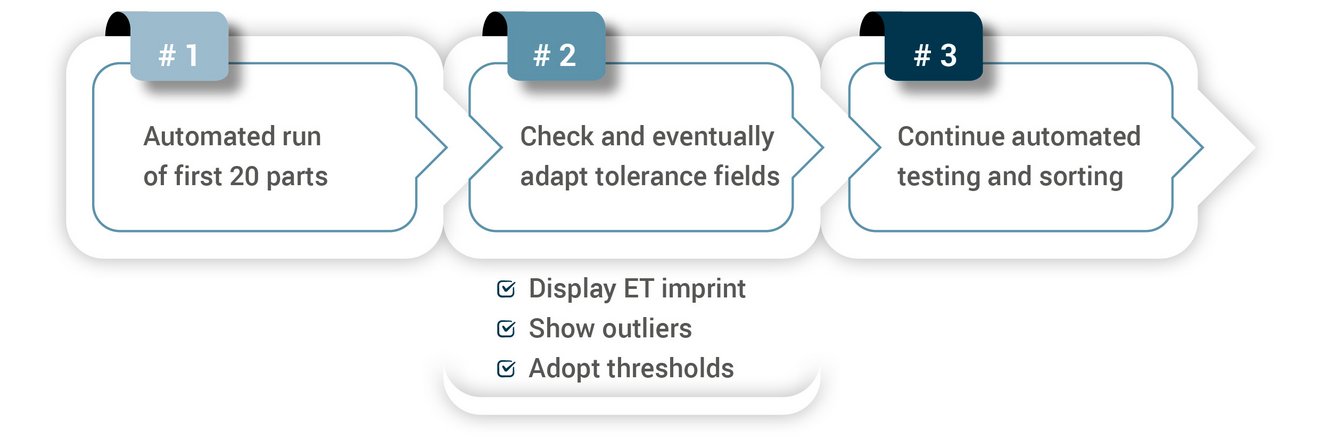

As one example, Fig. 3 shows the easy to use three step approach of teaching-in a new batch of fastener parts for eddy current testing. It requires only one part with comparable geometry for compensation. Based on an initial test run of 20 to 30 regular parts, the system analyses the eddy current answer (influenced by magnetic permeability and electrical conductivity of the parts) and visualizes the results of all parts in 24 frequency related tolerance fields. It also marks and shows outliers from the average, typical an ellipse shaped tolerance field. The operator eliminates the outliers, and the systems calculates the new thresholds for ok parts. Based on that, the system continues to test and sort. At a later step, the lab may analyze the outliers in closer detail and re-teach the system.

Three steps to teach-in new batches or types

applied in the Dimac MCV4 machine

Further advantages of ibg Technology combined with Dimac MCV4 automatic 100% sorting and inspection machines can be listed as follows:

- Machine and its sensoring devices handle complex geometries thus serve a wide range of fasteners

- Multi frequency evaluation with 24 tolerance fields on each part broaden the range of imprints of magnetic permeability and electrical conductivity for better detection of variation of parts

- Different tolerance fields can be analyzed

- Highly sensitive eddy current sensors, respectively encircling or fork coils with compensation technology, enable reliable test results also at changing temperature conditions

- Easy to use, easy to learn visual three-step-process supported by acknowledged background algorithms to teach-in new batches or types of parts

- That allows for teach-in at production shifts without lab backup

- Only a limited number of ok parts required for teach-in

- Additional machine learning for more distinctive thresholds possible with both predefined not-ok parts as well as with investigated ok parts

Conclusion

Massimo Agrati, CEO of Dimac summarizes the relationship with ibg on the development of the new Dimac range of machines as “Our goal is to offer state of the art automatic 100% inspection & sorting machines for high quality fasteners, able to perform a full range of controls, including NDT by Eddy Current technology. ibg produces state of the art instruments with advanced Eddy Current technologies which are very easy to use and very performant. It was natural for us to realize that the integration of their devices into our machines would contribute to create high value to our offer proposition. The integration process has been very easy because both of our companies have the same spirit of cooperation, the result lead to very performant solutions in terms of productivity and reliability with an evident added value for our customers around the globe"

Fair in Stuttgart (from left):

Wolfgang Korpus (CTO Ibg),

Massimo Agrati (CEO DIMAC),

Dr. Christian Artmann (CEO Ibg),

Mauro Stanga (International Sales Ibg)

Resources

Contact Us