Discover precision and reliability with ibg's innovative Eddy Current Testing technology. Detect grinder burn and cracks, revolutionize ball inspection with AVIKO's high-speed scanner, and explore high-precision inspections with ibg's NDT systems. Benefit from over 40 years of NDT excellence, 35+ years of eddy current technology experience, and tailored solutions for your testing needs. Welcome to the future of precision testing with ibg!

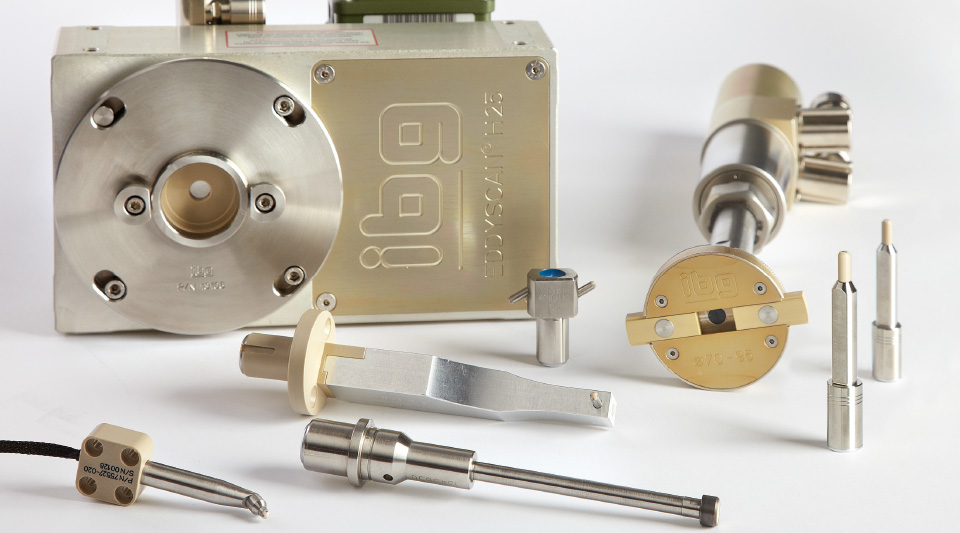

Hardness, Case Depth, Material Verification

Elevate your quality control with Eddy Current Testing. Discover how ibg's innovative technology ensures precision, efficiency, and reliability in inspecting critical components for hardness, case depth, and material composition.

Crack & Grinder Burn Detection

Enhance component reliability with advanced Eddy Current Testing. Discover how our non-destructive testing solutions detect grinder burn and cracks in metallic components for improved surface quality and safety.

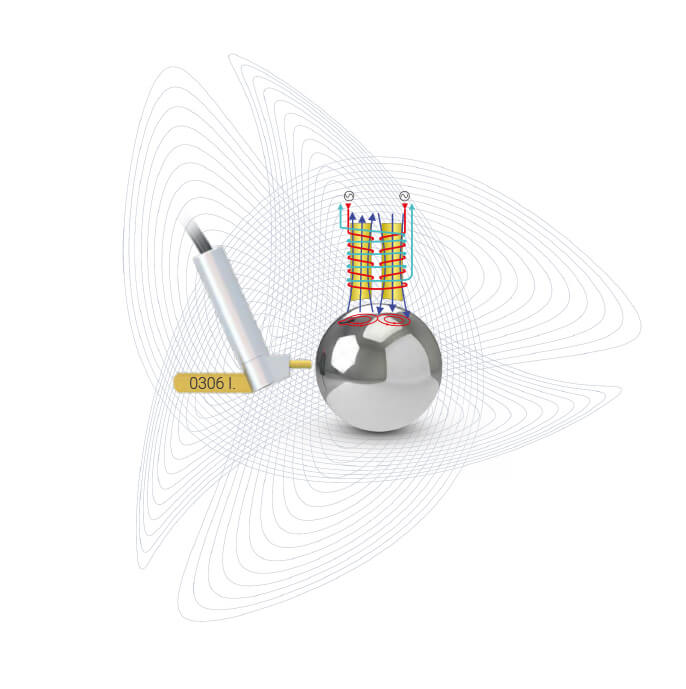

Bearing Ball Testing

Experience the future of ball inspection and sorting with AVIKO. Our high-speed ball scanner, offering precision and productivity, revolutionizes quality control for balls. Elevate your production process with AVIKO today!

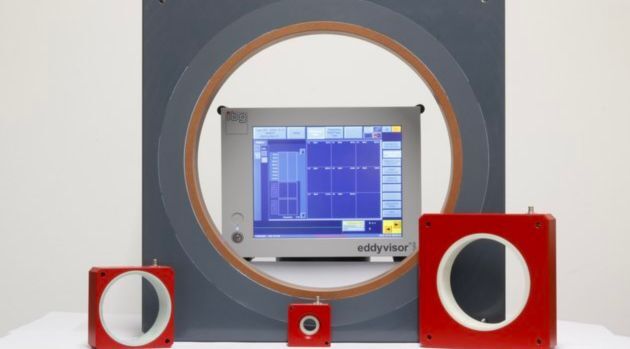

Systems and Devices

Discover how ibg's NDT systems elevate quality control, ensuring reliability and safety across industries. Explore high-precision inspections and efficient data management for compliance.

Elevate Your NDT Experience with ibg's Comprehensive Support Services

At ibg, we go the extra mile to ensure your NDT experience is seamless and exceptional. In addition to providing leading-edge technology, we offer a full range of services to meet your needs. From expert NDT consulting to guide you to the right solutions, seamless system integration to enhance performance, and comprehensive equipment training to improve your team's expertise, to regular equipment calibration and efficient spare parts and repair services to minimize downtime. Stay compliant and optimize performance with our annual certification and maintenance service from AVIKO. Rely on our comprehensive support services to enhance your NDT experience. Contact us today to enhance your testing capabilities.

Pioneering 40+ Years of NDT Excellence: The ibg Group Story

For over 40 years, ibg Group has pioneered eddy current testing. Founded by Herbert Baumgartner, we've consistently innovated to become a global leader in manufacturing eddy current instruments for non-destructive testing (NDT). Our innovations like Preventive Multi-Frequency Technology (PMFT) and Simultaneous Harmonic Analysis (iSHA) have redefined component testing. Trusted by industry leaders, we offer advanced digital test instruments and turnkey systems. In 2019, we added AVIKO Ball Scanner to our portfolio, with over 60 years of NDT expertise. We specialize in crack detection, temper line, grinder burn detection, and high-precision diameter sorting for various industries. Experience NDT excellence with ibg Group and AVIKO Ball Scanner.

Elevate Quality Assurance: Your Advantages with ibg's Eddy Current Technology

Your Benefits:

- Over 35 years of expertise in eddy current technology

- Global leadership in manufacturing eddy current testing equipment for non-destructive material testing (NDT)

- Industry-shaping innovations and inventions by our developers

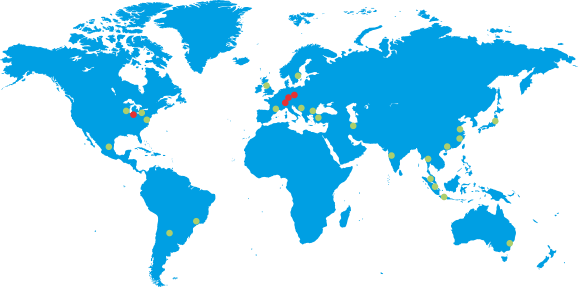

- Multiple locations and a robust partner network

- Worldwide clientele in the industrial and automotive engineering sectors

- Comprehensive quality management aligned with customer needs, market trends, international standards, and regulations.

Introducing Our New Lineup: Precision Bearing Ball Testing Systems

We're thrilled to announce the recent acquisition and seamless integration of Sorting Solutions into the ibg group. With over 50 years of product history, Sorting Solutions has been a key player in designing and manufacturing specialized machinery for inspecting ball quality, diameter, and various physical attributes.

Beyond our standard offerings, we take pride in tailoring custom solutions to meet your unique requirements. Collaborating with over 50 global companies in the bearing ball production industry, we provide a diverse array of sorting solutions. Our cutting-edge machines and probes are meticulously crafted to cater to various materials, whether it's ceramic, steel, or plastic. Explore the future of precision testing with ibg today!

Explore our Bearing Ball Testing Systems