Annual NDT Equipment Check-Up and Maintenance Services

Even the best inspection technology is not immune to aging or inadvertent misuse leading to directly visible or worse hidden defects and problems. Therefore standards like DIN EN ISO 15549 “Non-Destructive Testing - Eddy Current Testing” or IATF 16949 demand a preventive regular check-up of instruments and sensors by a qualified organization, normally in a periodicity of one year. Possible deviations as well as corrective measures have to be documented in a protocol.

During their annual visits, auditors like to verify check-up labels at our NDT instruments, in order to control the date of the last check-up. Overdue dates always will lead to demerits in the report of the audit.

Comprehensive NDT Equipment Check-Up: On-Site or Worldwide Service

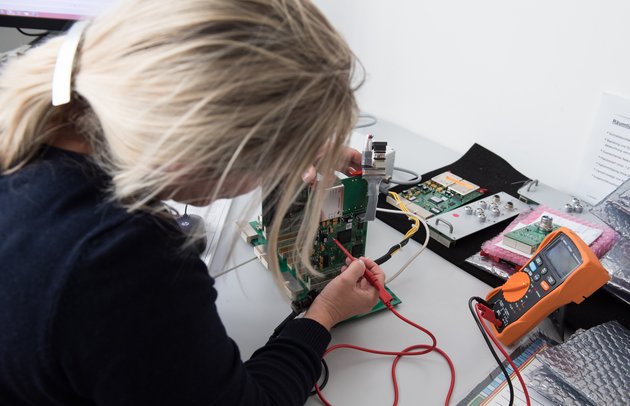

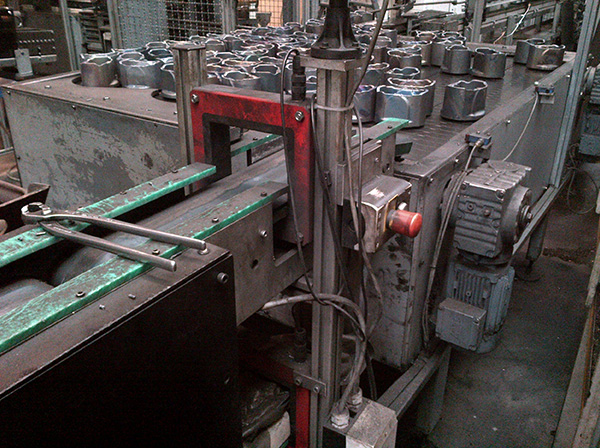

As a producer of your test equipment, we are best suited to offer you the yearly check-up of your ibg instruments. Typically, our technicians will arrange a visit to your production facility with you to carry out the check-up on-site and without removing the instruments from its system environment. But you can always also ship your ibg instrument to one of our company locations or to selected ibg partners worldwide for a check-up. Where applicable, we follow DIN EN ISO 15549, and, depending on the instrument type and its use, the following items will be checked and performed by our qualified technicians:

- Visual inspection, checking of the operational conditions

- Back up and later restore the project file (configurations, adjustments, and test data)

- Checking all relevant functions

- Checking of crack and/or structure signals by a special ibg simulator device

- Control of sensors and coil cables

- Final functional test with a test run

- Check-up protocol, check-up label

Yearly Check-Up for ibg Testing Equipment: Beyond Calibration

Important to know: this yearly check-up of ibg testing equipment is not a calibration in the classical meaning, but a functional check of the equipment according to ibg manufacturer standards. Due to the fact that eddy current testing is a comparative method, a classical calibration, meaning a comparison of a measured value with a known standard, is not possible, as the result of an eddy current test is always a comparison of the parameters of a test part with the parameters of the calibration parts.

Ready to ensure the reliability of your NDT equipment? Contact us today for a comprehensive yearly check-up and maintenance service.

Contact Us