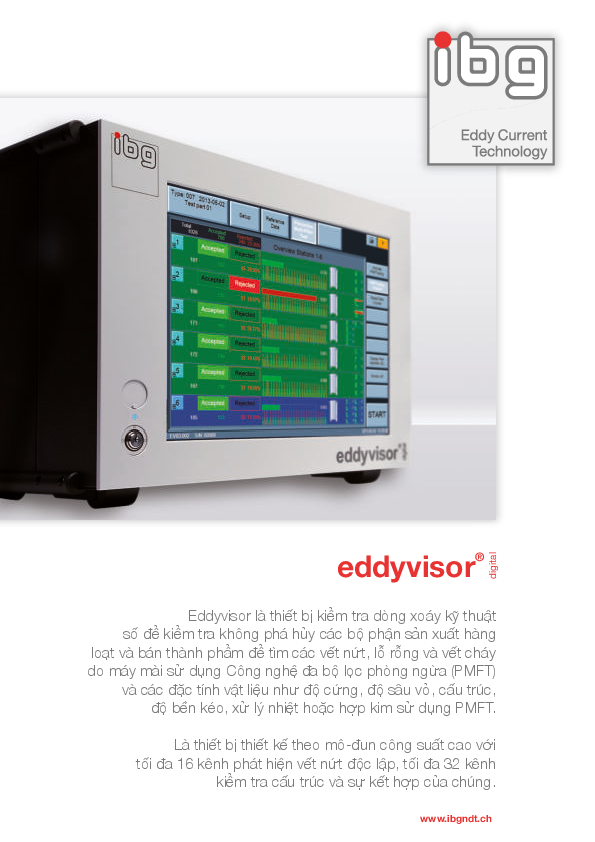

eddyvisor S: Masterpiece Eddy Current Structure Testing for Demanding Systems Integration

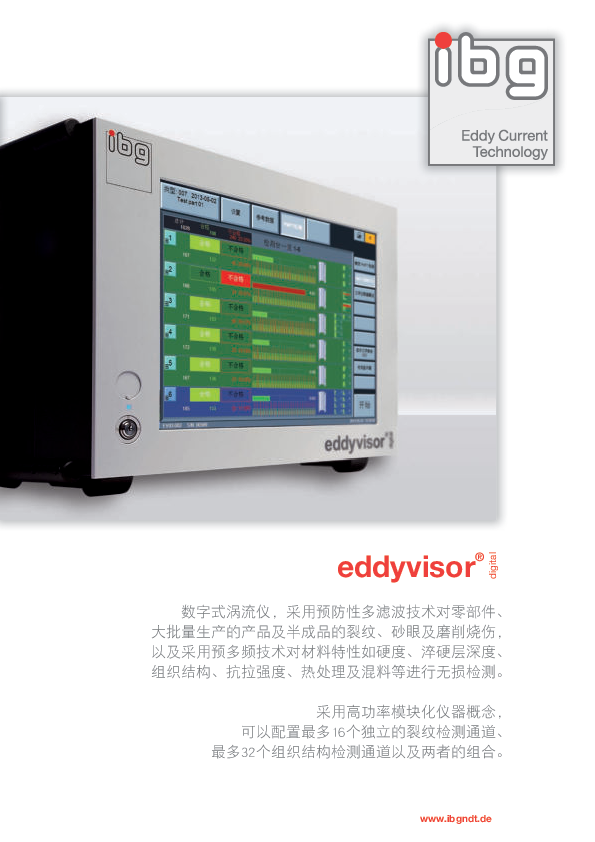

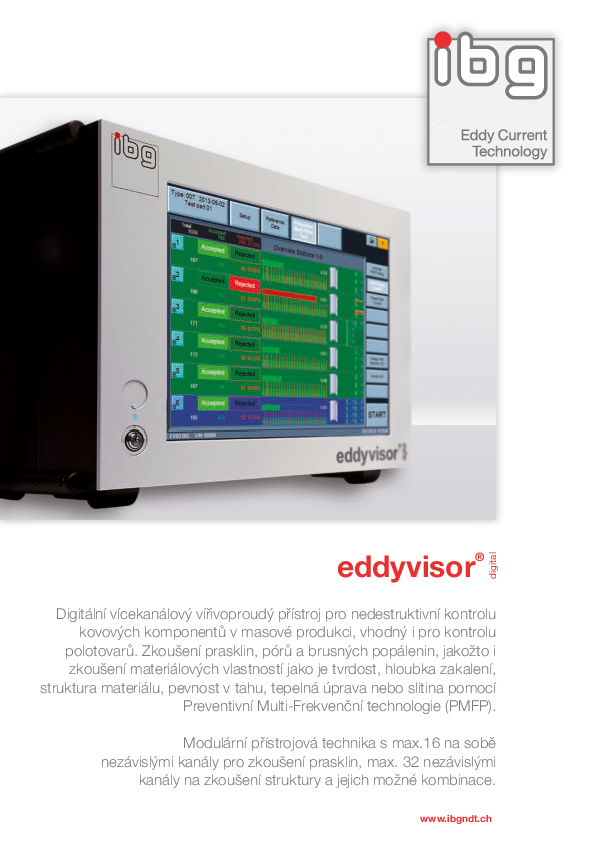

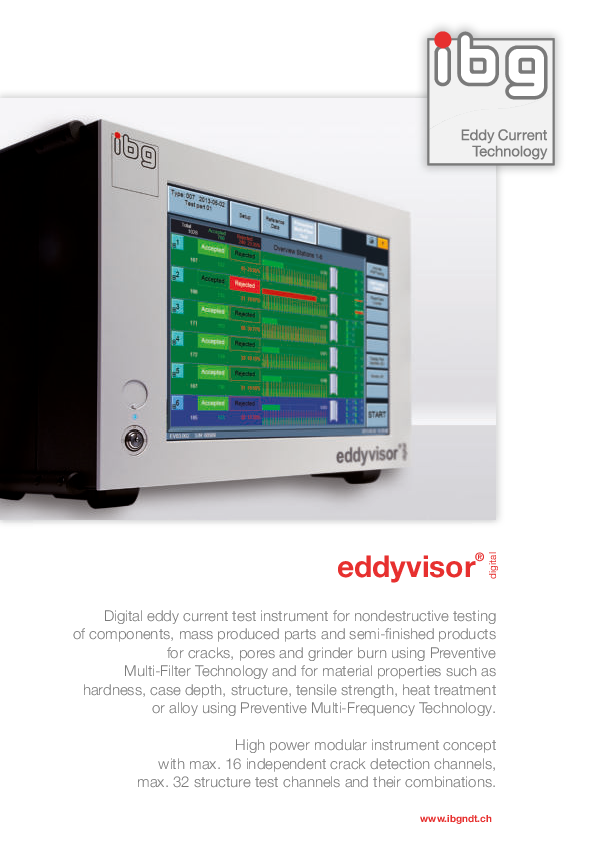

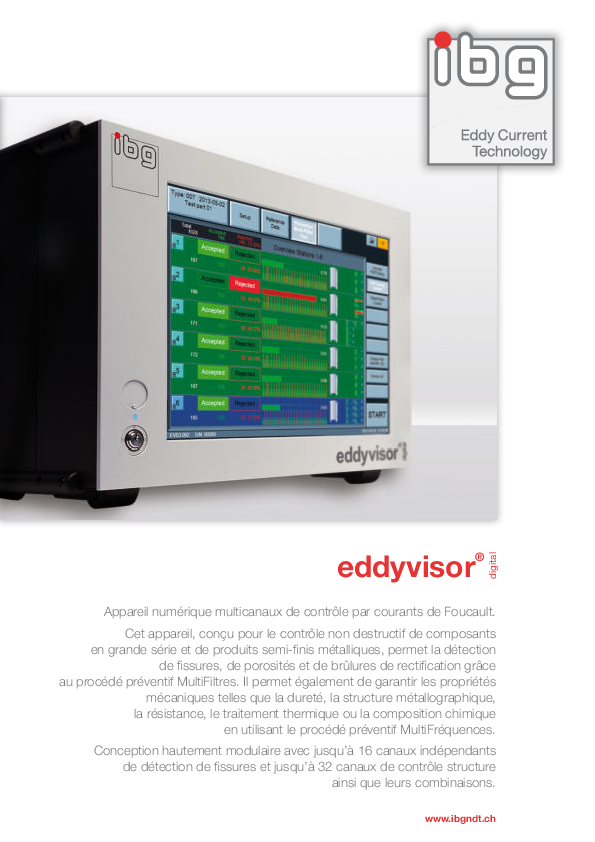

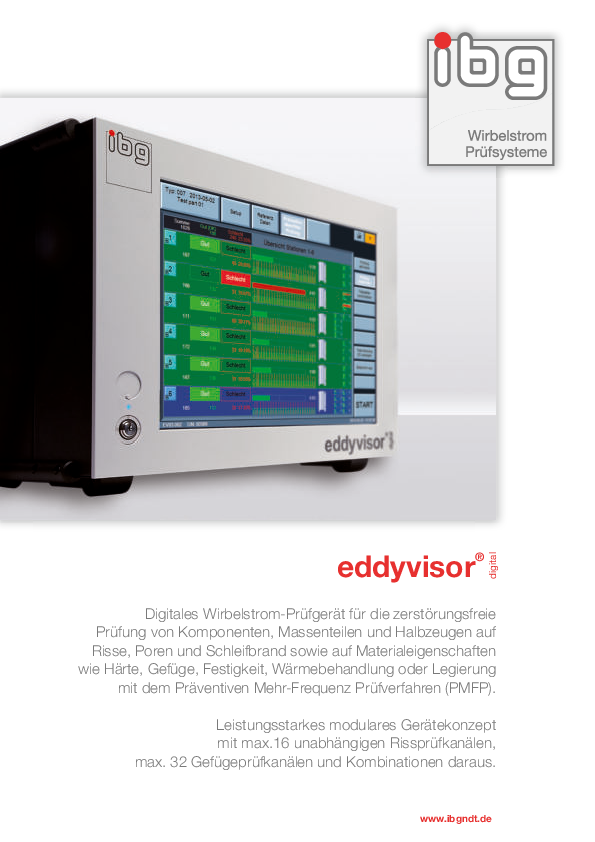

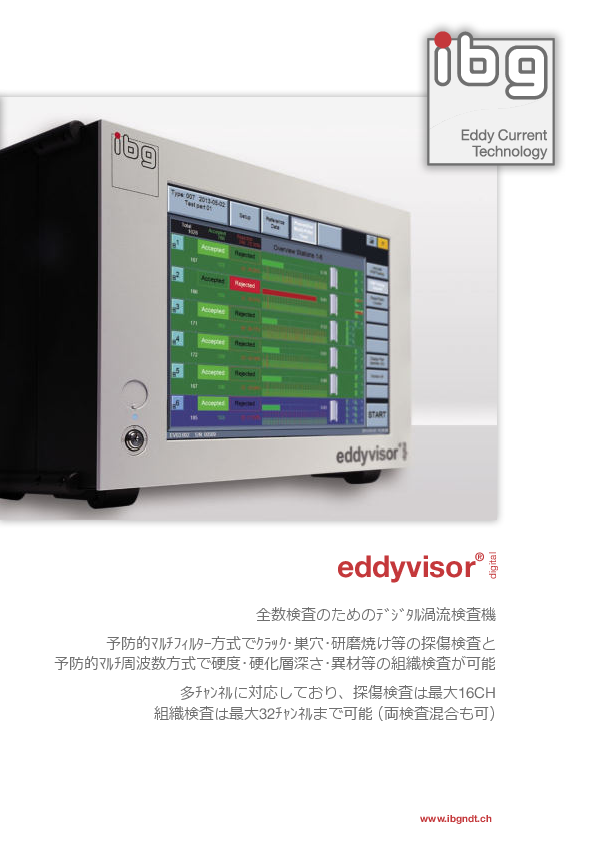

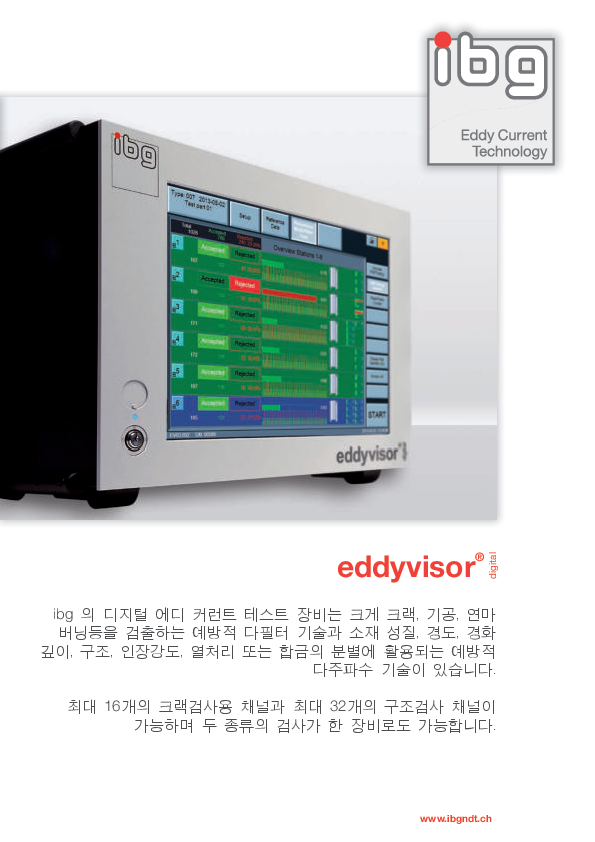

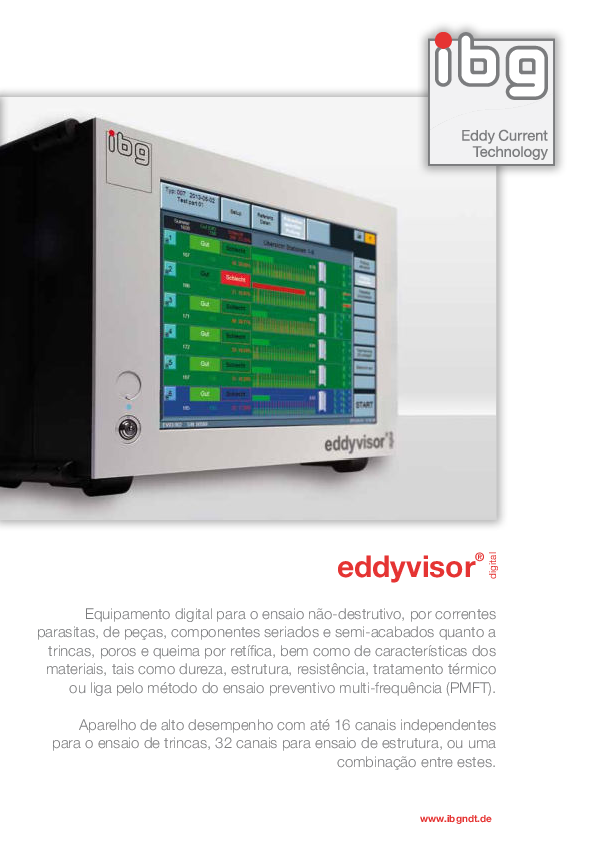

Digital eddy current test instrument for nondestructive testing of mass-produced parts, metal components, and semi-finished products for material properties such as hardness, case depth, structure, tensile strength, heat treatment, or alloy using ibg´s Preventive Multi-Frequency Technology.

Unveiling the Power of eddyvisor S: Versatile Features and Outstanding Reliability

The eddyvisor S distinguishes itself with its high-performance modular concept with max. 32 structure test channels in a very compact design. Additionally, it offers unique features for the realization of sophisticated test tasks using the eddy current technique, combined with the well-known ibg test reliability and ease of operation.

The ergonomic interface enables easy and simple operation via a touchscreen. All functions and test results are captured at a glance. Digital processing of the measuring signal with unique processors, immediately after the pre-amplifier guarantees the greatest possible stability of test results.

The Potential of eddyvisor S: A Versatile Solution for Advanced Material Testing

The eddyvisor is based on the long-proven ibg system concept. All coils, probes, rotating heads, and other system components are standardized worldwide. So eddyvisor is the solution for new tasks and to upgrade existing production machines to equip them with state-of-the-art eddy current technology.

ibg’s eddyvisor as high power modular concept instrument is available in three versions:

eddyvisor S

– max. 32 structure test channels

– for demanding material property testing

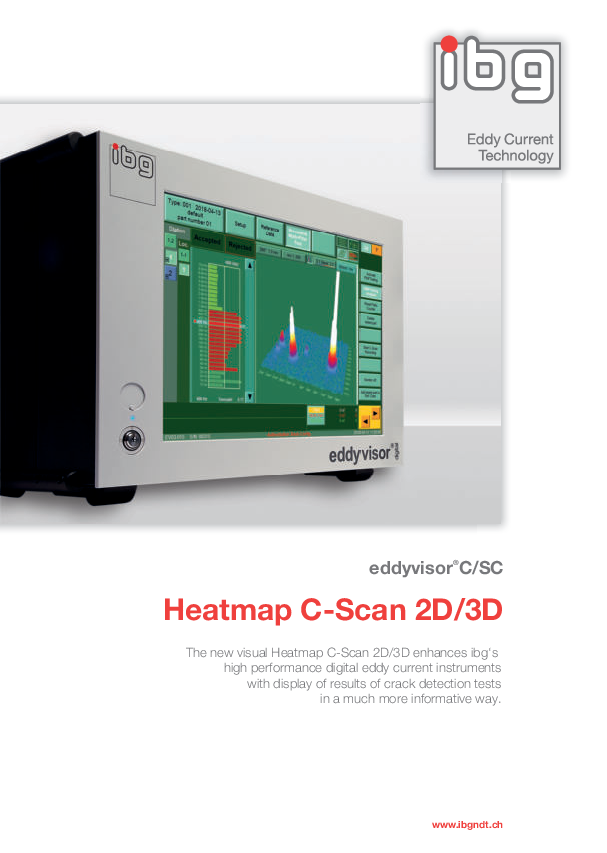

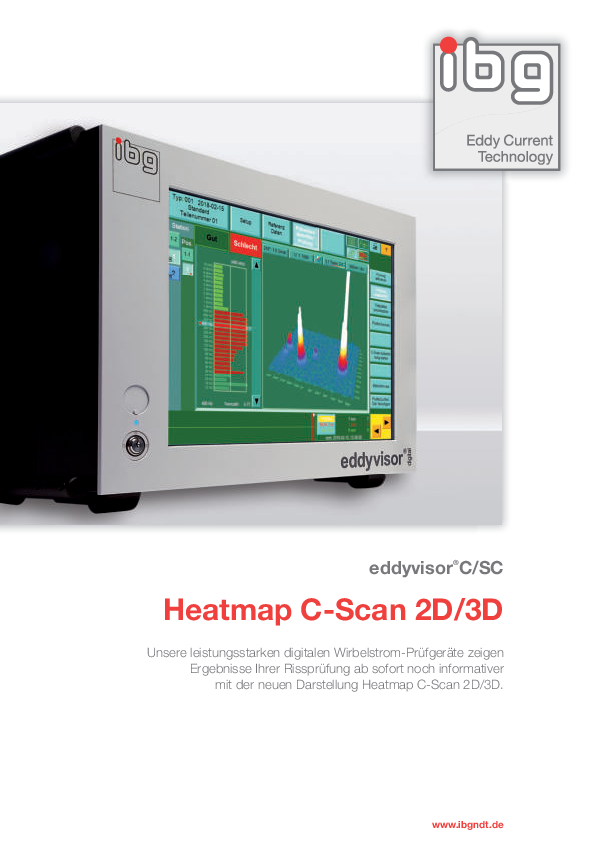

eddyvisor SC

– structure and crack test channels combined

– for crack and structure testing at the same

– typically systems integrated

eddyvisor C

– max. 16 independent crack test channels

– for crack and grinder burn testing

Advanced Technical Data Features of eddyvisor S

- User-friendly interface for all operators

- Clear presentation of functions and results

- Ensures ease of use for all skill levels

- Up to eight defined stations

- Each station accommodates up to 32 locations

- Stations are independent, allowing different operating conditions

- Adapt settings on the fly for various tasks

- Available for stations with 2 to 22 locations

- Visual representation of the test part

- Color-coded test results on the test part image

- Store up to 100 part types (or 250 in structure testing)

- Manual or PLC switching for automated processes

- Associate test data with individual parts using alphanumeric serial numbers

- Enhances traceability

- Multi-colored histogram for test results and reference data

- Stores data on the last 100 bad parts and up to 1,000 good parts

- Efficient crosschecking and analysis

- Secure storage internally on a robust SSD and externally via USB

- Log test results via a network connection

- Ring buffer logfile for expedited debugging

- Transmit test data via Ethernet to a protocol computer

- Complies with AQDEF standards for the QSSTAT interface

- Configure data storage options per test station

- Manage data from multiple ibg instruments within a single Ethernet network using eddyLogger software

Overview of Information about eddyvisor

Connections

| IO-ports | Optically insulated interface with an 32 in- and 32 outputs for PLC connection. As an option, a second module with additional 32 in- and 32 outputs can be installed. An allocation of the signals to the IOs is free in the eddyvisor. |

| Network | Gigabit Ethernet |

| XVGA | The screen may be displayed on another screen in XGA resolution by means of the HDMI and display port connector. Essential for trainings. |

| Printer | Commercially available printers may be connected via USB 2.0 or Ethernet to print out test results. |

| USB | Two USB ports at the back, one underneath for data storage. |

Technical Data

| Screen | Tough 15” TFT touch screen, color display, resolution 1024 x 768 pixels, operable with gloves. |

| Housing | Two models of eddyvisor are available: the Desktop version eddyvisor D (with retractable feet, inclined) or as a separated switch panel version with operating unit eddyvisor HMI and measuring unit eddyvisor M. |

| Power supply | 100-240 V, 50/60 Hz |

| Ambient temperature | 0 - 45°C |

| Relative humidity | max. 85%, non-condensing |

| Dimensions (WxHxD) / Weight | eddyvisor D 430 x 335 x 271 mm / 13 kg eddyvisor HMI 410 x 308 x 96 mm / 6 kg eddyvisor M 410 x 308 x 175 mm / 7 kg |

Available for download:

Catalogues of our eddy current instruments

The catalogs are also available in other languages. Click here to go to the download center

Contact Us